The admixture of one pigment only - namely 10 parts CIRCOLIT®-Slurry - to a standard topcoat calcium carbonate formulation can improve laser- and inkjet coding simultaneously.

CIRCOLIT®-Slurry leads to a good laser ablation as well as kaolin. Because of its ability to improve inkjet printability at the same time, kaolin can be completely omitted. By adding only one pigment - CIRCOLIT®-Slurry - two functionalities (laser and inkjet coding) can be created.

A switch to 90 parts GCC (grain size 90 / 95 % < 2 µm) and 10 parts CIRCOLIT®-Slurry often leads to reduction of binding agents compared to formulations with higher amounts of kaolin. The optimal amount of binder agents needs to be determined. It depends on complex factors, like rheology, precoated board and the coating application system. It is often reported that inkjet- and laser coding functions remain unchanged even with lower coat weights.

Regarding handling and runability, the use of CIRCOLIT®-Slurry is unproblematic. The tendency to reduce blade streaks is often praised compared to operating without CIRCOLIT®-Slurry.

Another functionality of CIRCOLIT®-Slurry is the excellent coating-opacity performance. Therefore, it is often used as an opacity inducing pigment in precoats for GD-board.

The adaption of various paper machines proves the high p

erformance of CIRCOLIT®-Slurry and its interesting economic efficiency.

Printing of DataMatrix-Codes on pharmaceutical folded boxes

is usually performed by drop-on-demand (dod) printers.

The quality of inkjet coding depends on the coating quality. The most common defect is smearing of the DataMatrix-Codes.

Because of that, smear resistance is measured after a very short time. For this test the board is printed and after a predefined time pressed against a wiping unit. Verification of the print is then performed offline by a verifier in accordance with DIN EN ISO/IEC 15415. Following factors are observed during the test: symbol coding, symbol contrast, axial unevenness

, grid unevenness, error correction and modulation as well as pattern errors.

Only 10% CIRCOLIT®-Slurry in the topcoat leads to sufficient smear resistance and achievement of the requested criteria with the common Inkjet label printers.

The high absorption volume as well as the fast absorption speed are also needed in other applications, for example coated qualities for high speed inkjet.

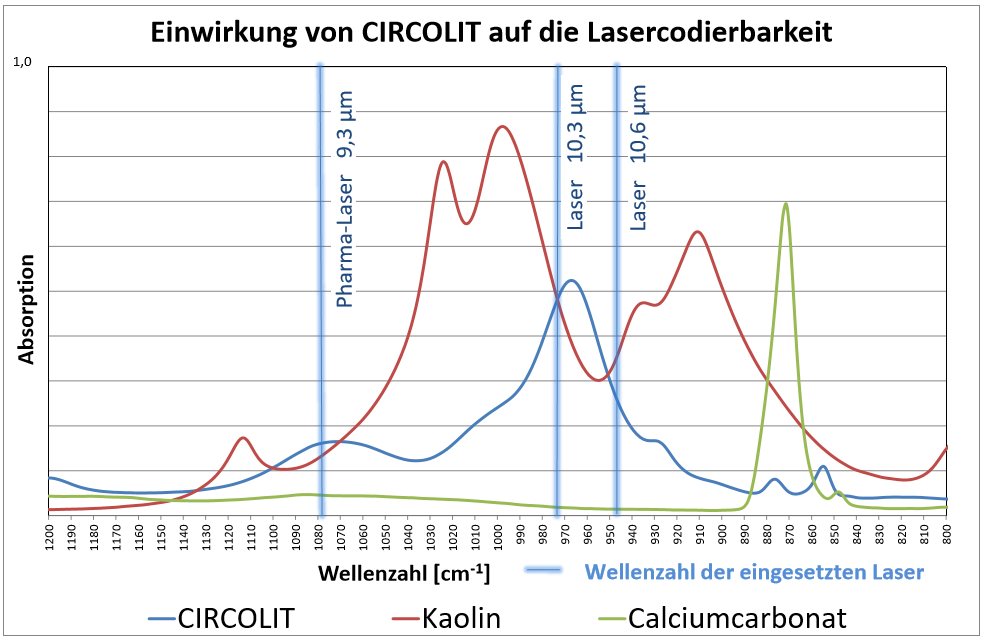

The most common used marking lasers (CO2-Laser) in the industry work with wavelengths of 9.3, 10.3 and 10.6 µm. The absorption of CIRCOLIT®-Slurry in all these relevant wavelengths is significantly better than CaCO3.

Kaolin, showing the same good absorption capabilities for these laser printers, can be omitted completely.

The surface layer will be engraved or evaporated fast and precisely with CIRCOLIT®-Slurry. An amount of only 10 % will do for the top-coat.

According to the Falsified Medicines Directive 211/62/EU implemented in February 2016 it is obligatory in the future to label every pharmaceutical package with an individual mark.

The goal of this directive is to fight medicine falsifications to protect patient’s safety. For this protection the directive provides two safety features:

A basic requirement for the success is an optimal coding ability of the board, which in turn requires an optimal coating of the board.

During labelling with laser, a fast and precise ablation takes place on the surface layer, whereby an abrasion-resistant code is created.

Coding via inkjet means the unique identifiers are printed directly within the packaging plant onto the folding box for a complete product traceability and reliable forgery protection.

The challenge here is that the inkjet codes need to be dry and smear-resistant within 0.3 seconds. Only then the codes meet the criteria according to DIN EN ISO/IEC 15415 and comply with FFPI-guideline (Forschungsgemeinschaft Faltschachteln für die Pharmaindustrie).

Further information:

Forschungsgemeinschaft Faltschachteln für die pharmazeutische Industrie